And less work.

I picked this up for free, works well, just need to know how to adapt it to my sander.

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Drum sander power feed systems http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=4940 |

Page 1 of 2 |

| Author: | Rod True [ Mon Feb 06, 2006 9:44 am ] |

| Post subject: | |

So, for those of you who have built your own drum sanders, do you have a power feed system? If so, I'd like to see some pics and ideas to make one on my home built sander. I'm tired of pushing the wood through. Any help? |

|

| Author: | Daniel M [ Mon Feb 06, 2006 10:25 am ] |

| Post subject: | |

I have a feed roller type system on my sander & it works really well. 1 3/4" rollers with 60 grit cloth glued on in a spiral pattern. Even with a roller system, you have to be ready to "assist" the wood once in a while. Especially if you try to hog off too much in one pass. I found a 1/4 HP, 60-1 reduced gear motor on Ebay & it has tons of power for the job. I'll try to find some pics & post them for you. The one downside of a power feed system is that you can't take as big a bite as you can with a hand feed system. Since the rollers won't slow down, you can only skim off as much as the feed speed will allow. If I try to take off too much at a time, the wood stalls & the drum sands a big divot in it. Even though it's a bit slower, I like the feed system a lot. It's safe to do alone & there's little chance of firing a chunk of wood across the shop. |

|

| Author: | Rod True [ Mon Feb 06, 2006 12:07 pm ] |

| Post subject: | |

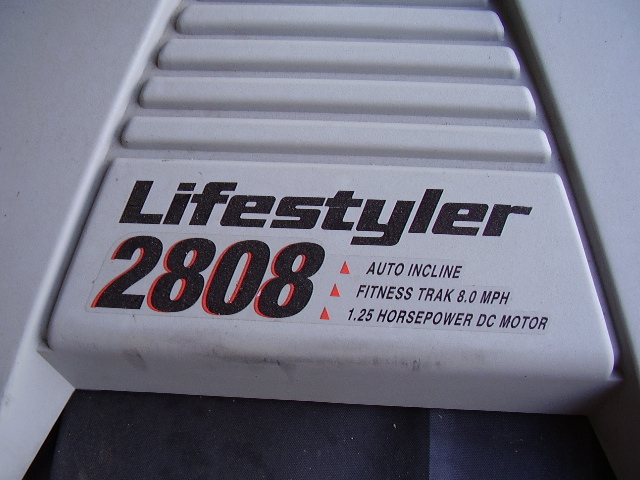

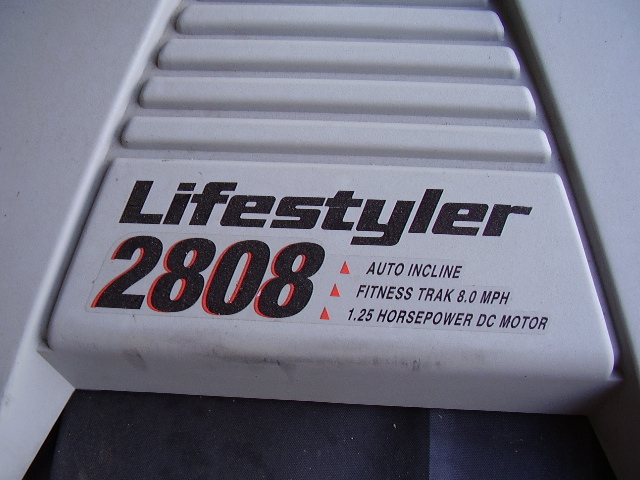

And less work. I picked this up for free, works well, just need to know how to adapt it to my sander.

|

|

| Author: | Rod True [ Mon Feb 06, 2006 12:13 pm ] |

| Post subject: | |

I know Mario built his. Wonder if He'll be able to help too. |

|

| Author: | Grant Goltz [ Mon Feb 06, 2006 3:19 pm ] |

| Post subject: | |

Rod, I built mine, too. I have a feed roller system, infeed and outfeed rollers, wrapped with sandpaper like Dan's. Mine is built very similar to the feed rollers on my old (1970 or so) Sears planer (actually build by Foley-Belsaw). Nothing fancy, but it works. Runs off the same motor as the drum via a system of speed reducing pulleys and belts. Grant |

|

| Author: | Cocephus [ Mon Feb 06, 2006 3:47 pm ] |

| Post subject: | |

I`ve been kicking around an idea of putting a rubber roller on the outfeed side of the drum with a crank so you can "feel" the load on the machine. This way you could also get the piece through the machine quicker should you get in a jam. Rod, looks like you have a good idea with the treadmill, but what are ya gonna hang your dirty clothes on now? |

|

| Author: | Daniel M [ Mon Feb 06, 2006 7:49 pm ] |

| Post subject: | |

I was thinking about a hand crank roller system when I designed my machine. There's no reason it wouldn't work well. It would be almost as easy to twin an infeed & outfeed roller on a single belt. It really is nice having both rollers. Rod; There should certainly be enough gear in that machine for an excellent system. Make sure you don't toss out the wiring diagram. It'll probably be on an inpection panel somewhere. Were the pics I sent you helpful? |

|

| Author: | sfbrown [ Mon Feb 06, 2006 10:04 pm ] |

| Post subject: | |

I happened to check out the power feed mechanism on Powermax last Friday and they use a 1/10 hp - 40 rpm gear motor on a conveyor bed with approx 1" rollers. They use a 60 grit sander belt for the conveyor belt. My only question is how to lag (rubberize) the drive pulley. And then of course there's the need to suspend it and make it adjustable. Hmmm... Steve |

|

| Author: | Rod True [ Tue Feb 07, 2006 2:10 am ] |

| Post subject: | |

Steve, what about using plasti-dip to lag the pulley?

That's what I was thinking of using. My only question is what to use for the conveyor belt. |

|

| Author: | Shane Neifer [ Tue Feb 07, 2006 2:15 am ] |

| Post subject: | |

A wide belt sanding belt. Or the rubber mat on your conveyor on the tread mill Shane |

|

| Author: | Rod True [ Tue Feb 07, 2006 2:36 am ] |

| Post subject: | |

I guess I could find the belt, it needs to be 22" wide as that is the width of my deck. Or, I guess it only needs to be as wide as the widest back/top I will put through it right? We don't want the back to overlap the belt or there will be a difference in thickness. |

|

| Author: | Pwoolson [ Tue Feb 07, 2006 2:46 am ] |

| Post subject: | |

Hey Rod, I think you have a good thing with that treadmill. I wouldn't worry about altering it. Just remove the "handles" and all the plastic junk and you've got a nice long infeed bed. The tracking is already set on the thing so I'd use it as it is. Just build the sander around it. |

|

| Author: | Rod True [ Tue Feb 07, 2006 3:04 am ] |

| Post subject: | |

Nice idea Paul, but the bad thing about it is that my sander is already built (you probably knew this), your right though. |

|

| Author: | Mario [ Tue Feb 07, 2006 3:28 am ] |

| Post subject: | |

Yeah, I built my sander, but I bought a Performax power feed unit for it <bg> |

|

| Author: | Rod True [ Tue Feb 07, 2006 5:19 am ] |

| Post subject: | |

Ow, come on Mario, I was countin' on you for the ultimate home build here.

|

|

| Author: | Mario [ Tue Feb 07, 2006 6:33 am ] |

| Post subject: | |

It's the wise man who knows when to stop making, and start buying <g> Actually, the reason I built my sander wasn't to save time or money, but rather because the sanders I'd used all had issues I thought I could build around, and we did. The feed wasn't an item I thought we could improve upon a whole lot; there's just not much to them... |

|

| Author: | Rod True [ Tue Feb 07, 2006 6:38 am ] |

| Post subject: | |

[QUOTE=Mario] It's the wise man who knows when to stop making, and start buying <g> [/QUOTE] Yes, but it's the pocket book that keeps telling me to build these darn things and forget about buying them.

I don't mind giving the time as for me this is a hobby so I usually just throw out the "time is money" factor. |

|

| Author: | Serge Poirier [ Tue Feb 07, 2006 9:46 am ] |

| Post subject: | |

Rod, i wish i knew how to post a link, on a woodwork forum from Australia, maybe the Aussie friends like Kiwi could tell us the name, there is a guy there who shows how he did his. Looks easy but don't know how to link it here? Serge |

|

| Author: | Rod True [ Tue Feb 07, 2006 9:48 am ] |

| Post subject: | |

Serge just copy and past, that will be fine. |

|

| Author: | sfbrown [ Tue Feb 07, 2006 10:03 am ] |

| Post subject: | |

[QUOTE=Rod True] Steve, what about using plasti-dip to lag the pulley? That's what I was thinking of using. My only question is what to use for the conveyor belt.[/QUOTE] Its a thought but I think I may use a 3/4" shsft and force on some 1/8" wall medium duro urethane. It can be purchased through some specialty houses. I'll let you know if I can find it. Isn't the belt a commercially available sanding belt? Like the hand held belt sanders but wider. Looking at the joint on the Powermax, it is either that or you can buy a replacement belt from Powermax. The joint appeared to be a production item. When I get some time I'll check into it. Oh, did I mention that I work for an industrial distributor? I sometimes design conveyors. Usually, they aren't this small though!

Regards, Steve |

|

| Author: | sfbrown [ Tue Feb 07, 2006 10:06 am ] |

| Post subject: | |

[QUOTE=Mario] Yeah, I built my sander, but I bought a Performax power feed unit for it <bg>[/QUOTE] Where did you get it? From Powermax direct? What was the cost? It might be cheaper to buy than to build. Thanks, Steve |

|

| Author: | A Peebels [ Tue Feb 07, 2006 10:51 am ] |

| Post subject: | |

Steve To rubberize the roller, go to your local electrical supply house, and buy some self vulcanizing rubber high voltage splicing tape. There are two varieties, one with a liner and one without. the tape must be stretched to 1/2 of its origional width and applied with even pressure in an overlapping spiral of approxamatly half lap. Build up layers until the tape is about 1/8 inch thick. The tape will bond to itsself and the irregularities can be sanded out. Al Peebels |

|

| Author: | Mario [ Tue Feb 07, 2006 11:06 am ] |

| Post subject: | |

Steve, I bought it from a tool supplier; forget who. These used to be available seperately, as they were an option on the radial arm saw conversion kits. At 24" wide, it was perfect for me... It's the same as the power feed for a 25" SuperMax. |

|

| Author: | PaulB [ Tue Feb 07, 2006 12:32 pm ] |

| Post subject: | |

Hi Serge, Is thisthe one you were talking about? |

|

| Author: | Rod True [ Tue Feb 07, 2006 12:55 pm ] |

| Post subject: | |

Thanks Paul. |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|